ABB - Contrac – Actuators For Highly Dynamic Control Loops

Continuous electrical control in continuous operation “ S9 ”

For more than 50 years, ABB control actuators have met all requirements for process control world wide. This experience makes it possible for us to offer the intelligent Contrac actuators with an extended functional scope and therefore more value for the user.

As an ABB sales partner we would be pleased to submit a quotation on Contrac control actuators, Contrac electronics and Contrac spare parts as well as actuators and spare parts from the old ST/RST/RH/RHA/RS control actuators programs.

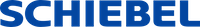

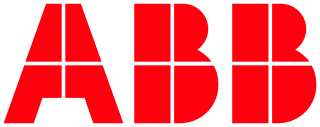

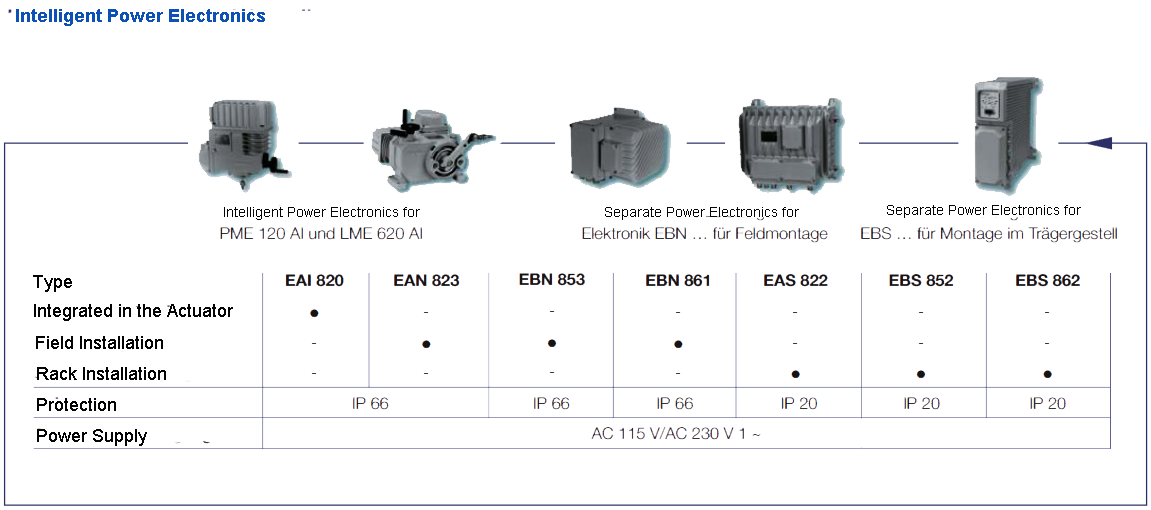

The program includes part turn actuators with control torques of 50 Nm to 16000 Nm and linear actuators with control forces of 2 KN to 100 KN. The unit is controlled either by an integrated electronic system (IP 66) , by an electronic in field housing (IP 66) or by an electronics for a rack (IP 20) in the power controller cabinet.

Strong Advantages

- Easy commissioning

- Ability to communicate via RS232, Hart or Profibus

- Configurable via graphical user interface

- Integrated service hosts for demand-oriented maintenance

- Integrated process controller with transmitter supply

- Extensive self-diagnosis

Continuous Positioning

- Smooth, virtually wear-free operation; also at step operation

- No increased starting current

- High positioning accuracy

Blocking Resistance

- No limit or torque dependent switch off

- Continuous operation S9 without limitation

- Exceeds the requirements of the highest class "continuous modulation class “D” according to EN 15714-2" by far.

Robust, Oil-Lubricated Gearboxes

- Low lots and high efficiency by spur gears / ball screw

- Long service life with minimal maintenance

- Regular maintenance every 10 years

- High performance at low motor power

- Blocking of current position through integrated motor brake by failure or disconnection of the supply voltage

Customized Configuration

- Frequency control enables an individual optimization of the control loop

- Control forces , torques and operating times adjustable

- Individual adjustable end position behavior for tight closing, with selectable break - away torque from the end position with increased torque

- Extensive report and diagnostic functions facilitate the fault localization

- Operation on conventional 1-phase mains, voltages with large tolerance range - AC 115V - 230V AC

Graphical User Interface

With the engineering tool Asset Vision Basic, data exchange is made possible with the intelligent electric control actuators. The communication software is used for parameter display, configuration, diagnosis , support of service and maintenance activities, data management and documentation. FDT / DTM technology allows remote programming of a process control system.

Adjustable to 50% ; 75% ;100% control torque

Adjustable to 50% ; 75% ;100% control torque Adjustable to 50% ; 75% ;100% control force

Adjustable to 50% ; 75% ;100% control force

Many actuators also in Ex - Design

Explosion protection II 2 GD ck EEX de [ ib ] ib II B T4 etc. IP 6 x T = 130°C ZELM 04 ATEX 0209 X